Ag-waste for Renewable Energy and Carbon Sequestration

Western Tilth and Power & EnerLaunch, LLC

The US needs more renewable energy and carbon sequestration to meet Net-Zero goals.

1.2.1. Background

"Road to Removal: Options for Carbon Dioxide Removal in the United States, Lawrence Livermore National Laboratory, 2023."

By 2050 we need:

-

1Gt of annual CO2 emissions reduction

-

1Gt of annual CO2 removal needed

-

The US Generates 488 million tonnes/yr of crop residue.

It’s estimated that up to half of it can be recovered.

Western Tilth & Power uses distributed pyrolysis plants to process ag-residues into energy, soil and climate products.

Electricity

2MWe of firm (24/7) renewable electricity per plant

Biochar

Maximized recovery of biochar for sale into ag & industrial markets

Carbon Credits

Sequestered CO2 is eligible for carbon removal credits

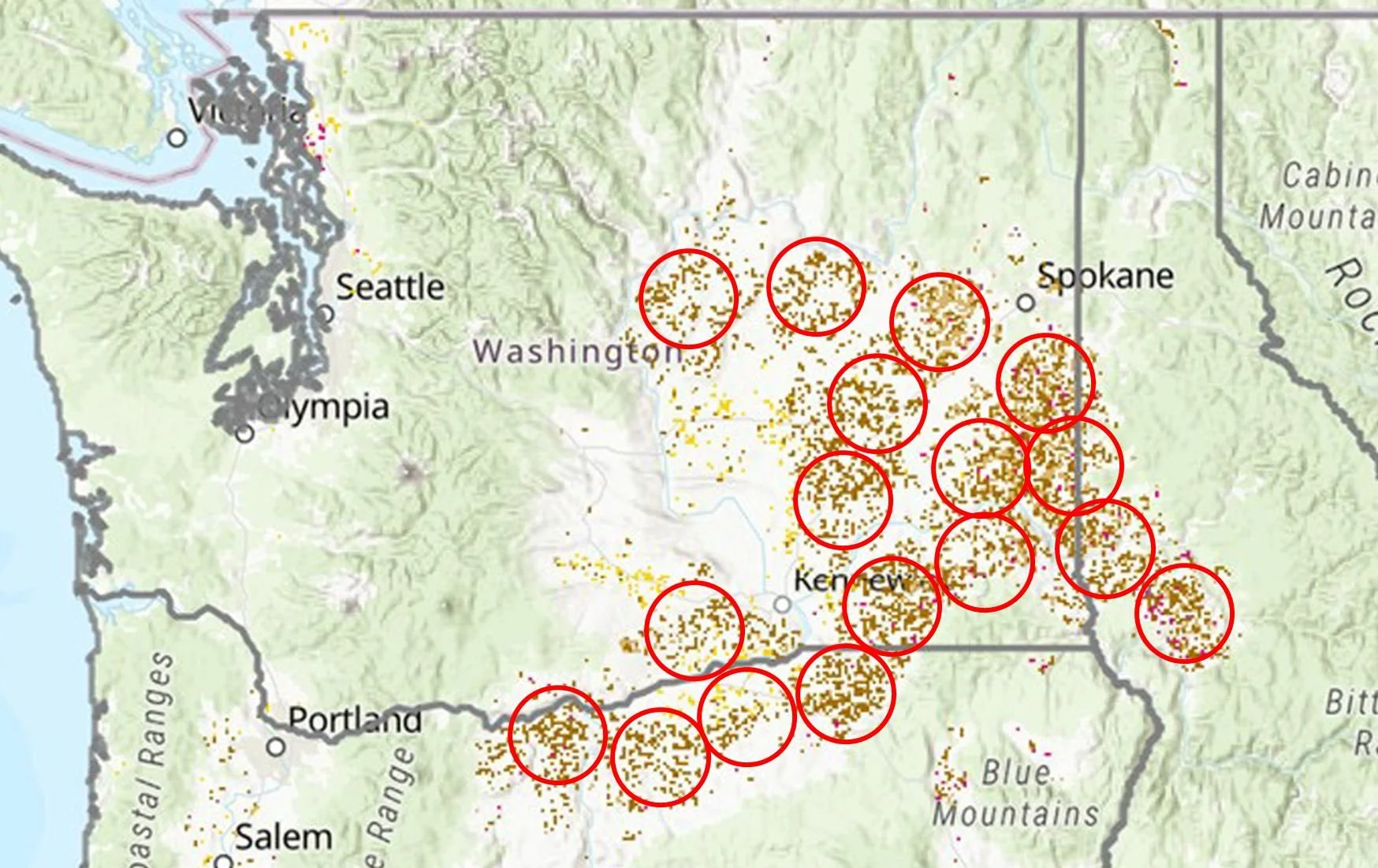

We’re bringing agricultural, energy and climate opportunity to rural communities, starting in the Pacific Northwest.

The PNW is a significant source of agricultural residues.

Western Tilth and Power is targeting distributed plants at 4 tonnes/hr wheat straw feedstock.

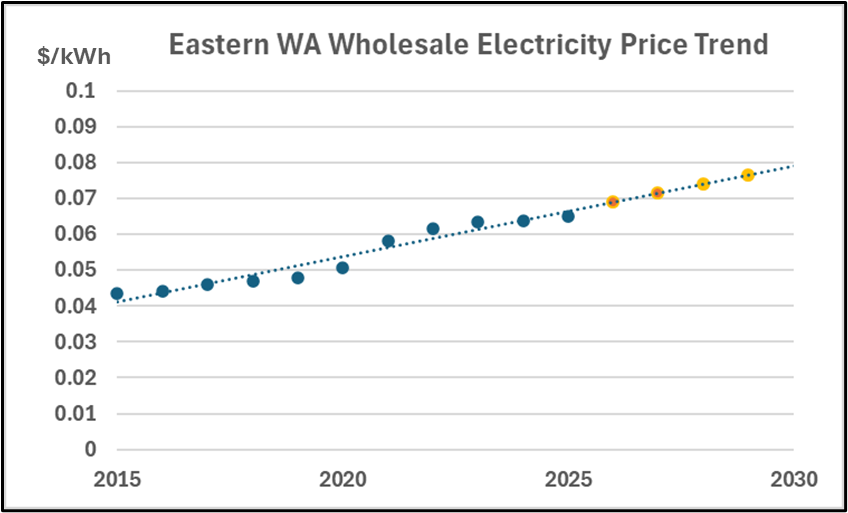

Rural communities struggle with rising power costs, limited renewable energy access, few green job opportunities, barriers to carbon market participation, dependence on imported fertilizers and challenges from dry conditions requiring electric irrigation.

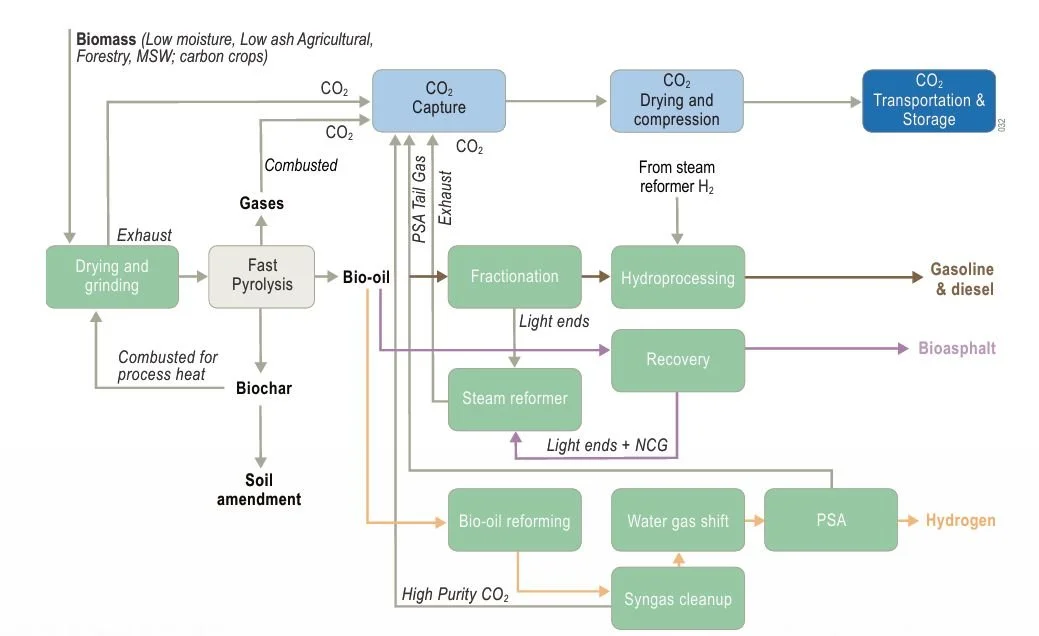

WTP utilizes a simplified pyrolysis process.

1.2.2. Technology

We’ve simplified the pyrolysis process to create robust energy generation:

Direct combustion of pyrolysis vapors

Closed, steam cycle using modern steam generation

Feedstock pre-conditioning for stable, dense storage

Our plants will produce:

24/7 electricity

Biochar (Soil amendment & CO2 Removal)

Process heat (capable)

Typical pyrolysis processes focus on cooling, collection and conversion of difficult to handle pyrolysis gases and liquids to fuels and chemicals.

"Road to Removal: Options for Carbon Dioxide Removal in the United States, Lawrence Livermore National Laboratory, 2023."

This process focuses on existing technologies using off the shelf components.

WTP’s processes remove condensation and handling of pyrolysis vapors and maximizes energy recovery by combusting the effluent while hot, recovering energy in standard power system equipment.

The field-to-field biochar cycle optimized:

1.2.3. Deployment

Feedstock Sourcing

Conservative plant placement will allow for growth while demonstrating regional capability.

A 15 mi radius is assumed to define plant feedstock delivery for each plant: 452,400 acres

Taking conservative estimates:

• 30% area devoted to wheat

• 1 crop per year

• 1/3 of available straw per acre removed (1ton/ac removed)

371 tonnes per day available.

Electricity Product

Each plant will produce 2MWe of non-intermittent power.

Rural Electric Cooperatives (RECs) serve a major fraction of targeted agricultural communities.

Discussions with RECs indicate strong interest in firm, renewable energy. Customers can sell feedstock to the plant that generates electricity for Cooperative members.

RECs in the PNW are seeking new generation and prefer distributed sources under 5MWe. RECs balance peak load by additional purchases from balancing authority. Primarily this is irrigation load from their agricultural customers.

Biochar Product

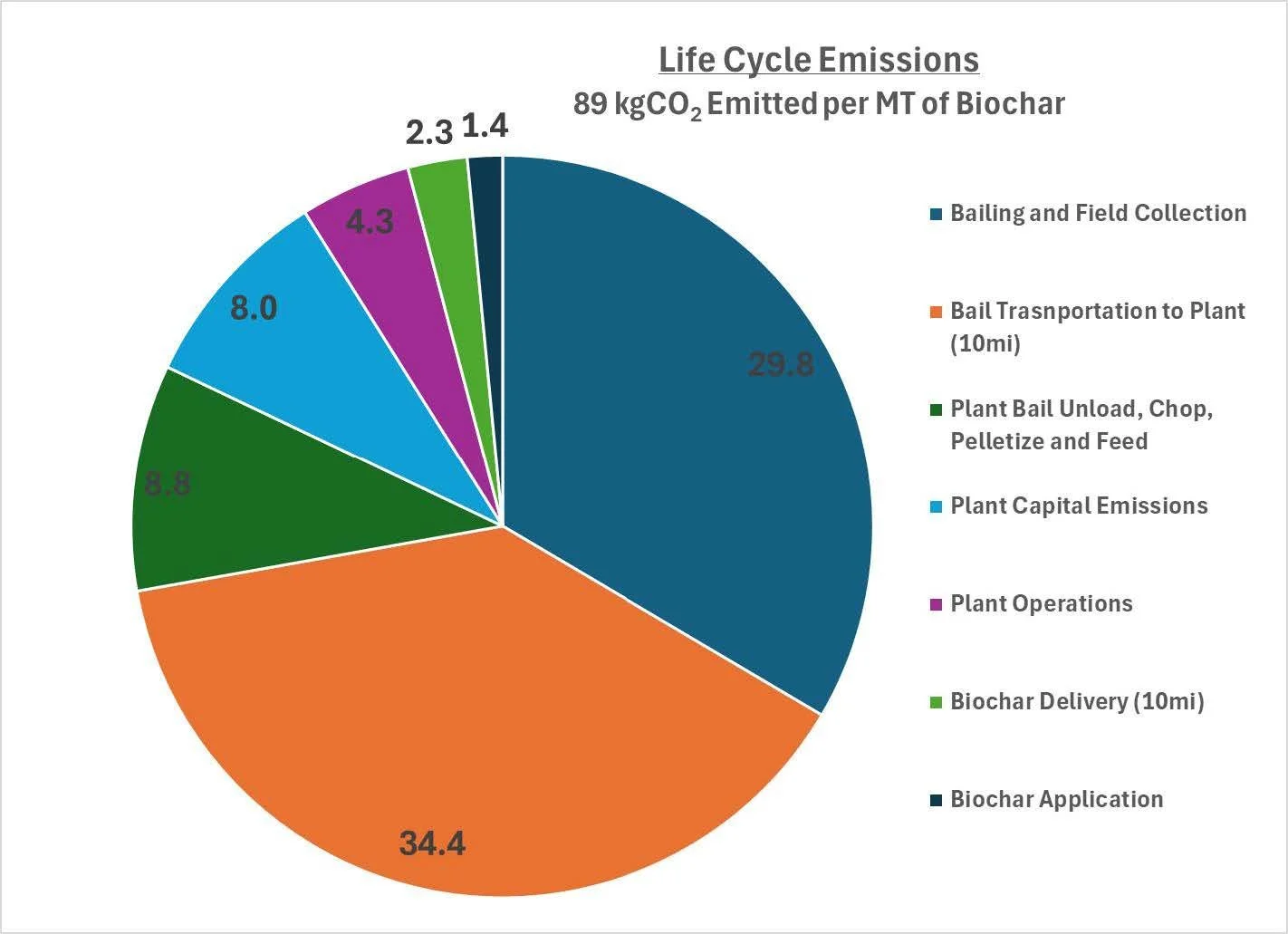

Biochar is a stable form of carbon produced by heating biomass without oxygen, offering long-term environmental stability that makes it an effective tool for carbon sequestration.

Each plant will produce 8,000 tonnes per year of stable biochar.

Each ton of biochar can sequester 2-3 tons of CO2 and may qualify for certified CO2 Removal Certificates (CORCs), providing both climate benefits and potential revenue streams.

It represents a historically important soil component that has been largely absent from modern agricultural systems, providing active habitat necessary for redeveloping soil's natural micro-biome.

Beyond supporting soil biology, biochar contains essential plant nutrients (nitrogen, phosphorus, and potassium) while improving soil structure and water retention capacity.

The Biochar market is being accelerated by private companies offsetting emissions.

1.2.4. Markets

Major technology companies are driving significant investment in carbon removal markets, with Microsoft establishing a $1 billion Climate Innovation Fund that includes multiple biochar investments, while Google, Meta, Stripe, McKinsey, and Shopify created Frontier to purchase $1 billion in carbon removal credits.

The Frontier initiative has already contracted 492,000 tons at an average price of $311 per ton of CO2, with ambitious targets of scaling to 2.5-5 billion tons annually.

The biochar carbon offset market is becoming increasingly structured, with registries like Puro.earth establishing public indices such as the CORCCHAR Index at €136 per ton of CO2 as of February 2025.

1.2.5. Scaling

Each Plant will remove 20,000MT of CO2 from the atmosphere, per year.

First Plant:

8,000 MT of annual biochar production, 20,000 MT of CO2

Regional Build-out:

17 Initial plants per region: 340,000 MT CO2

Plant On-site Expansion:

2-4 Plants per site: 0.7-1.4 Million MT CO2

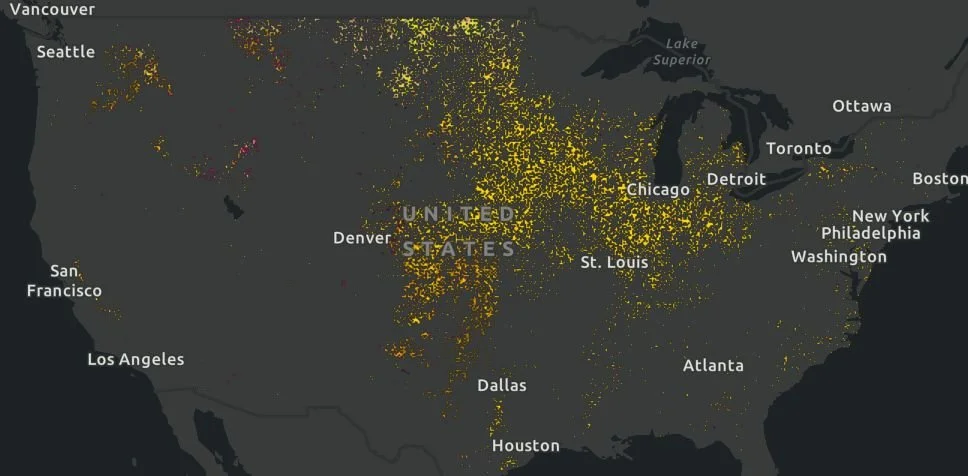

The potential for crop residue based sequestration extends well beyond the PNW.

The US and Canada have 165M tons of recoverable corn and wheat residue, annually.

U.S.

92M acres of corn

42M acres of wheat

Canada:

27M acres of wheat

4M acres of corn